Optimum Toughness Grains Brown Fused Alumina, suite Ad Abrasives Et Refractorie

- Aluminium oxydatum Brown

- BFA

- Brown corundum

Description

Applicationem

Brown Fused Alumina lenta est, abrasiva acuta, quae valde apta est ad stridorem metallorum magnae distrahendi vires.Eius possessiones scelerisque praestantem materiam usui praestant in fabricando productorum refractariis.Haec materia etiam in aliis medicamentis adhibetur, sicut uredine et induratione superficiei.

| Gradus | Specification | Chemical Composition(F46) | ||||

| Al2O3 | SiO'2 | Fe2O3 | TiO2 | CaO' | ||

| Grade laterem * | 0-1,1-3,3-5mm-8+16,-16+30,-30+60mesh,fines | ≥95.2 | ≤1.0 | ≤0.3 | ≤3.0 | ≤0.4 |

| Castable Grade | 0-1,1-3,3-5mm-8+16,-16+30,-30+60mesh,fines | ≥95 | ≤1.5 | ≤0.3 | ≤3.0 | ≤0.4 |

| Vitrified Grade | F12-F220 | ≥95.5 | ≤1.0 | ≤0.3 | 2.2-3.0 | ≤0.4 |

| Resina & Blasting Grade | F12-F220 | ≥95 | ≤1.5 | ≤0.3 | ≤3.0 | ≤0.4 |

| Micro Gradus | P240-P1200 | ≥92-95 | ≤1.0-1.8 | ≤0.3-0.5 | ≤2.2-4.5 | - |

| F240-F1000 | ≥88-95 | ≤1.0-2.5 | ≤0.3-0.5 | ≤2.2-6.5 | - | |

| Liquescens punctum | 2050℃ | |||||

| Refractio | 1980℃ | |||||

| Verum density | 3.90ming/cm3 | |||||

| Mohs duritiem | 9.00min | |||||

| Items | Magnitudo | Chemical Compositio (%) | ||||

| Al2O3 | TiO2 | CaO' | SiO'2 | Fe2O3 | ||

| A和AP1 | F4~F80 P12~P80 | 95.00~97.50 | 1.70~3.40 | ≤0.42 | ≤1.00 | ≤0.30 |

| F90~F150 P100~P150 | 94.50~97.00 | |||||

| F180~F220 P180~P220 | 94.00~97.00 | 1.70~3.60 | ≤0.45 | ≤1.00 | ≤0.30 | |

| F230~F800 (P240~P800) | ≥93.50 | 1.70~3.80 | ≤0.45 | ≤1.20 | ≤0.30 | |

| F1000~F1200 (P1000~P1200) | ≥93.00 | ≤4.00 | ≤0.50 | ≤1.40 | ≤0.30 | |

| P1500~P2500 | ≥92.50 | ≤4.20 | ≤0.55 | ≤1.60 | ≤0.30 | |

| AB和AP2 | F4~F80 P12~P80 | ≥94.00 | 1.50~3.80 | ≤0.45 | ≤1.20 | ≤0.30 |

| F90~F220 P100~P220 | ≥93.00 | 1.50~4.00 | ≤0.50 | ≤1.40 | - | |

| F230~F800 (P240~P800) | ≥92.50 | ≤4.20 | ≤0.60 | ≤1.60 | - | |

| F1000~F1200 (P1000~P1200) | ≥92.00 | ≤4.20 | ≤0.60 | ≤1.80 | - | |

| P1500~P2500 | ≥92.00 | ≤4.50 | ≤0.60 | ≤2.00 | - | |

| AS | 16~220 | ≥93.00 | - | - | - | - |

Gradus lateris/vitrificati BFA : Producitur utens speciali gradu Bauxite in parametris fusione sobrie.Hic gradus aptus est ad Bricks/Vitrificata producta praecavens Cracks/Fissurae, Foramina et maculae nigrae in fine producti.

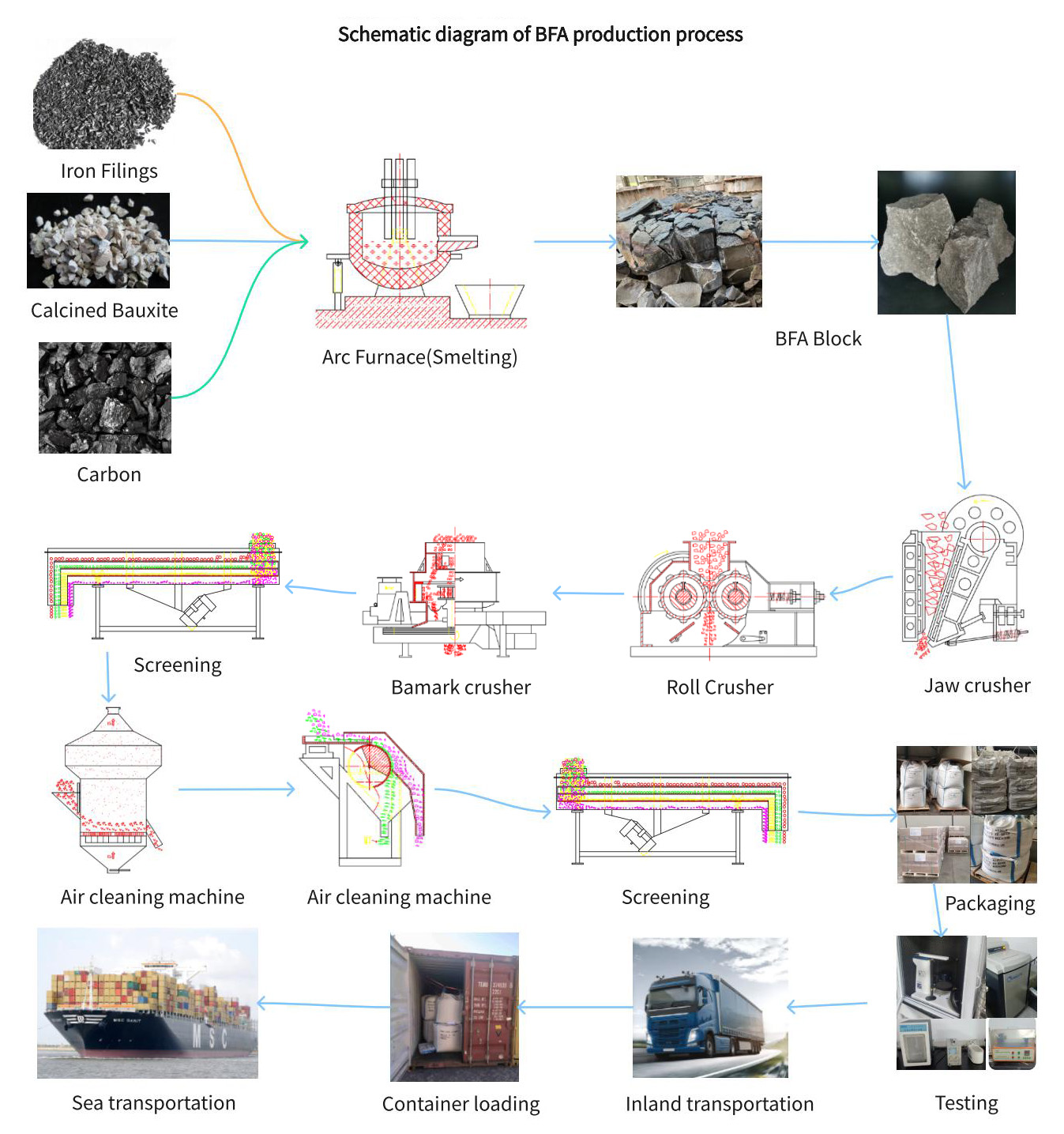

Processus productionis

Brown Fused Alumina gignitur ex excoquunti Bauxite Calcined in fornace electrico in temperaturis plus quam 2000°C.Processus solidificationis tarda sequitur fusionem, ut crystallus obtusus cedat.Auxilia liquefactionis ad tollendum residua sulphuris et carbonis, moderatio stricta super Titania gradus in fusione processus optimam duritiem granorum efficit.

Tum crudus refrigeratus ulterius tusus, magneticae immunditiae purgatur in magno intensione separatorum magneticarum, et in fractiones angustas magnitudine indicatur ad finem usui accommodatum.Lineae dedicatae producta pro diversis applicationibus efficiunt.